- Home

- Products

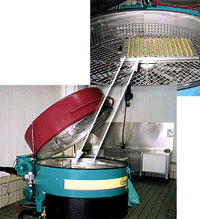

- Toploader - Cleaning machines

- Frontloader - Cleaning machines

- Conveying - cleaning machines

- Paint stripping system

- Brush washing table

- Accessories: Baskets

- Used machines

- Application examples

- Application example Maintenance: Cleaning of housings within a few minutes with the Clean-o-mat SP 80

- Application example: Paint stripping of wheel rins in a little while

- Special solution: Parts cleaning machine Clean-o-mat SP 80 with additional hand-spraying device

- Cleaning machine Clean-o-mat SP 80 - 2 T for turbine components out of the aircraft industry

- Degreasing of voluminous parts with the toploader Clean-o-mat SP 200

- Cleaning of valve housings with Clean-o-mat PF 150

- Removal of adhesive residues on grinding wheels with the Spray cleaning device Clean-o-mat RC 82

- Cleaner

- Request

- Services

- Company

- News

- Jobs

- Fair appointments

- Videos

- Topics

- 30 years of service Holger Illgen

- 30 years of service Zbigniew Woch

- Long - time - employee retires

- Honor for 35 years of service Ralf Schepers

- NEXION S.p.A. and STENHØJ GROUP join forces

- Trade fair participation at the “Technology 2017” in Tel Aviv/Israel

- Canadian partner exhibit at "CMTS 2017" in Canada

- 50 Years PERKUTE Maschinenbau GmbH

- Closing the gap in the Toploader series

- 30 years of affiliation with the company

- Quick paint stripping of wheel rims

- Paint stripping

- Customer satisfaction since almost 25 years

- Clean-o-mat SP 80 "Hardening shop"

- Clean-o-mat TW 105 "Cleaning plant with dual function"

- Clean-o-mat PF 150 "Pretreatment to the varnishing"

- Clean-o-mat RW 350

- Clean-o-mat TW 108: "Manufacturing"

- Clean-o-mat FR-90H "Manufacturing"

- Clean-o-mat SP 120: "Chocolate - factory"

- Clean-o-mat SP 160 "Prototype construction and part production"

- Clean-o-mat SP 80 "Produktion company"

- Clean-o-mat SP 160 "Road contruction company"

- Contact

- Download & Login

Please let us know!

Please let us know!